Upgrade Your Windows with Aluminum Tracks for Seamless Functionality

Introduction to Aluminum Window Tracks

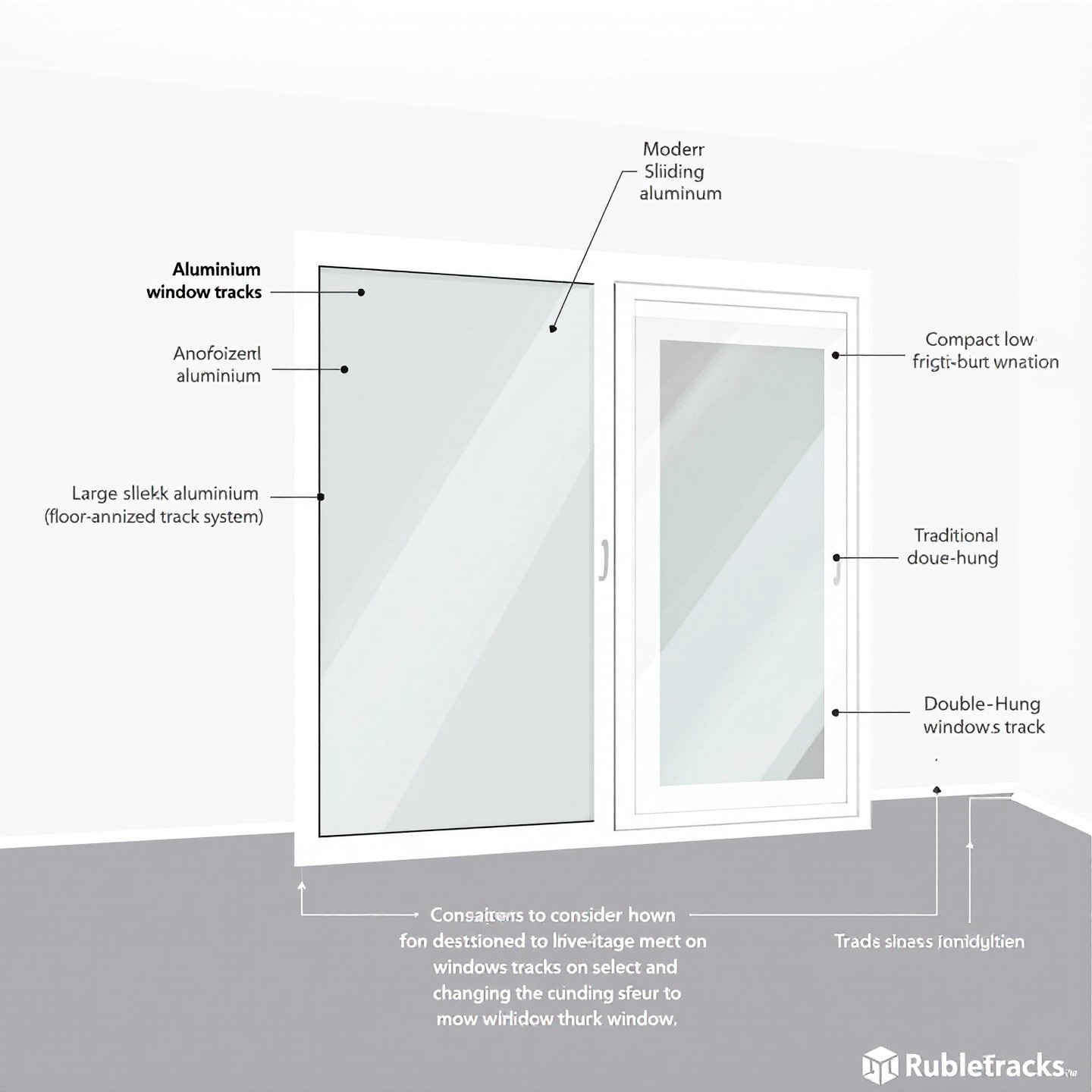

Imagine effortlessly gliding your windows open to let in a fresh breeze without the familiar creak or resistance. This seamless experience is made possible by the often-overlooked component of window systems: the aluminum window track. As a critical element in modern sliding window designs, aluminum tracks ensure not only smooth operation but also contribute significantly to the durability and efficiency of the window system.

Aluminum window tracks serve as the channels along which window sashes slide. Their design is pivotal in maintaining the structural integrity and functionality of sliding windows. Unlike traditional wooden or plastic tracks, aluminum tracks are renowned for their resilience to weather conditions and wear over time. This makes them an excellent choice for homeowners seeking long-lasting solutions for their window systems.

Why are aluminum sliding window tracks preferred over other materials? The answer lies in their unique properties. Aluminum is lightweight yet incredibly strong, providing a perfect balance that supports easy window movement without compromising on durability. Moreover, aluminum's resistance to corrosion ensures that these tracks maintain their functionality and appearance even in harsh environmental conditions.

For homeowners considering an upgrade or replacement, understanding the role of aluminum window tracks is essential. Whether you're looking at an aluminum window track replacement or installing a new system, these tracks offer a durable and efficient solution that enhances both the functionality and aesthetics of your home. As we delve deeper into the specifics of aluminum window tracks, you'll discover how these components can transform your windows into a seamless, efficient part of your home environment.

Understanding Aluminum Window Tracks

When you think about the components that make your windows glide effortlessly, aluminum window tracks might not be the first thing that comes to mind. Yet, these tracks play a pivotal role in the functionality and longevity of sliding windows. Acting as the pathway for window sashes, aluminum window tracks ensure that the windows open and close smoothly, enhancing both convenience and security.

The design of an aluminum window track system is both simple and ingenious. Typically, these tracks are constructed from high-grade aluminum, a material chosen for its remarkable properties. Aluminum is not only lightweight, which reduces the overall strain on window mechanisms, but it also boasts excellent resistance to corrosion. This makes it ideal for window tracks, which are frequently exposed to the elements.

Imagine the track as the highway for your window sash. It guides the sash as it moves, ensuring it stays aligned and operates efficiently. The precision in the design of these tracks is crucial. Even a slight misalignment can lead to operational issues, such as sticking or jamming, which can diminish the window's performance and lifespan.

Key Components of Window Track Parts

Understanding the window track parts is essential for appreciating how these systems function. The track itself is a channel, often lined with rollers or gliders, that the sash moves along. These rollers reduce friction, allowing for a smooth sliding motion. Additionally, the track may include weatherstripping, which serves to seal the window when closed, preventing drafts and enhancing energy efficiency.

The material composition of aluminum tracks directly impacts the window's durability. Aluminum's strength-to-weight ratio is unmatched, providing robust support without adding unnecessary weight. This balance is crucial in maintaining the structural integrity of the window over time, especially in larger installations.

In summary, aluminum window tracks are more than just a support structure. They are a key component that affects the ease of use, efficiency, and lifespan of your windows. As we explore further, you'll see how different track types and configurations can be tailored to meet specific needs, ensuring your windows not only look great but also function flawlessly for years to come.

Types of Aluminum Sliding Window Tracks

When it comes to enhancing the functionality and aesthetic appeal of your windows, understanding the types of aluminum sliding window tracks is crucial. These tracks are not one-size-fits-all; they come in various configurations, each designed to meet specific needs and preferences. Let's delve into the two primary types: two-track and three-track systems.

Two-Track Aluminum Sliding Windows

Two-track systems are a popular choice for many homeowners due to their simplicity and efficiency. In a two-track aluminum sliding window, there are two parallel tracks that accommodate two sashes. This setup allows for either one fixed and one movable sash or two operable sashes that slide horizontally. The beauty of this system lies in its space-saving design, making it ideal for smaller spaces where opening a window traditionally might not be feasible.

The installation process for two-track systems is relatively straightforward, which can be an advantage for DIY enthusiasts and can also help lower installation costs. Moreover, their minimalist design adds a classic appeal to both traditional and modern homes. However, it's important to note that while two-track systems are cost-effective and easy to install, they might not provide the same level of ventilation as their three-track counterparts, especially in warmer climates where airflow is essential.

Three-Track Aluminum Sliding Windows

For those seeking enhanced functionality, three-track aluminum sliding windows offer a compelling option. These systems feature three tracks and can accommodate up to three sashes, providing greater flexibility in terms of ventilation and airflow. In a typical three-track setup, you might have one fixed sash and two movable ones, or all three operable, allowing for more control over the amount of air entering the space.

The additional track in this configuration not only improves ventilation but also contributes to a unique and modern aesthetic. This makes three-track systems particularly suitable for contemporary homes or larger spaces where maximizing natural light and air circulation is desired. However, it's worth considering that the complexity of these systems can lead to higher installation costs and may require more maintenance to ensure smooth operation.

Choosing between two-track and three-track systems ultimately depends on your specific needs, the size of your space, and your budget. If you're working with limited space and a tighter budget, a two-track system might be the perfect fit. Conversely, if you're looking for a solution that offers superior ventilation and a modern look, investing in a three-track system could be worthwhile. As we move forward, understanding these configurations will aid in making informed decisions that enhance both the functionality and aesthetics of your home.

Benefits of Aluminum Window Tracks

When considering upgrades to your home’s windows, aluminum window tracks offer a range of benefits that make them an attractive choice for many homeowners. These tracks are not just components of a window system; they are integral to enhancing both the functionality and aesthetic appeal of your windows.

Durability and Longevity

One of the foremost benefits of aluminum window tracks is their exceptional durability. Aluminum is a material renowned for its resistance to corrosion and rust, which means these tracks maintain their structural integrity even in harsh weather conditions. This durability translates into a longer lifespan for your window systems, minimizing the need for frequent replacements or repairs.

Moreover, aluminum’s resilience to wear and tear ensures that your windows will continue to operate smoothly over time. This characteristic is particularly valuable in areas with extreme weather conditions, where other materials might fail.

Lightweight and Easy to Handle

Aluminum's lightweight nature is another significant advantage. This property makes the installation process more manageable and less labor-intensive compared to heavier materials. It also means that the window frames and tracks exert less stress on the building structure, reducing potential maintenance issues related to load-bearing.

Imagine the ease of operation when you open or close your windows; this smooth functionality is largely due to the lightweight yet strong nature of aluminum tracks. They allow for effortless movement, enhancing the user experience and making everyday tasks simpler.

Aesthetic Versatility

In terms of aesthetics, aluminum window tracks offer a sleek and modern look that complements a variety of architectural styles. Their clean lines and metallic finish add a touch of elegance to any home, whether contemporary or traditional. This versatility allows homeowners to integrate these tracks seamlessly into their existing decor, enhancing the overall visual appeal of their living spaces.

Furthermore, aluminum can be easily painted or anodized to match different color schemes, offering additional customization options to suit personal preferences.

In conclusion, the combination of durability, lightweight properties, and aesthetic versatility makes aluminum window tracks a superior choice for enhancing the functionality and appeal of sliding windows. As you consider options for your home improvement projects, these tracks provide a reliable and stylish solution that supports both practical needs and design aspirations.

Installation Guide for Aluminum Window Tracks

Installing aluminum window tracks may seem daunting at first, but with the right tools and a clear plan, it can be a straightforward process. This guide will walk you through each step to ensure a successful installation, whether you're replacing old tracks or setting up new ones. Let's dive into the essentials of how to install aluminum window tracks effectively.

Preparation: Gather Your Tools and Materials

Before you begin, it's crucial to have all necessary tools and materials ready. You'll need a tape measure, screwdrivers, a metal file, a hacksaw, and a small tube of clear silicone. Additionally, ensure you have the correct replacement window track and rollers for your specific window model. Taking an old roller to a hardware store can help you find an exact match if needed.

Start by removing the window sash carefully. Most sliding windows can be lifted out by tilting them slightly. If you encounter resistance, check for any locking mechanisms that might need to be unscrewed. With the sash removed, inspect the existing track for dirt or damage, which can impede the installation process.

Step-by-Step Installation Process

- Clean the Track Area: Use a vacuum or a damp cloth to clean the track thoroughly, removing any dirt or debris that could affect the new track's placement.

- Measure and Cut the New Track: Measure the length of the old track and cut the new aluminum track to size using a hacksaw. It's okay if the new track is slightly shorter, as this can ease the installation process. Use a file to smooth out any rough edges on the cut track.

- Apply Silicone Adhesive: Apply a thin bead of silicone adhesive along the underside of the new track. This will help secure it in place. Be sure to start and stop the adhesive about an inch from each end to prevent excess from squeezing out.

- Position the New Track: Carefully position the new track over the existing one, ensuring it aligns properly. Gently press down along the track's length to secure it in place. If the old track is uneven, use a hammer and a thin block of wood to gently tap the new track into position without bending it.

- Reinstall the Window Sash: Once the track is securely in place, lift the window sash back into position. Slide it back and forth gently to ensure smooth operation and that the track is correctly aligned.

- Allow for Adhesive Curing: Leave the window slightly open to let the silicone cure fully, which usually takes about 24 hours. This ensures the track remains firmly in place.

Final Checks and Adjustments

After installation, perform a final check to ensure everything is in working order. Slide the window back and forth to confirm smooth operation. If you notice any sticking or misalignment, adjustments may be necessary. Regular maintenance, such as cleaning and lubricating the track, will help maintain its functionality over time.

By following this window track installation guide , you can enhance the performance and longevity of your sliding windows, ensuring they operate smoothly for years to come. Whether you're a DIY enthusiast or a homeowner looking to improve your living space, installing aluminum window tracks is a valuable upgrade that combines functionality with ease of use.

Maintenance Tips for Aluminum Window Tracks

Maintaining your aluminum window tracks is essential for ensuring their longevity and smooth operation. Regular maintenance not only enhances the functionality of your windows but also prevents costly repairs and replacements. Here, we provide practical tips to help you keep your aluminum window tracks in top condition.

Regular Cleaning

To maintain aluminum window track systems effectively, start with regular cleaning. Dust and debris can accumulate in the tracks, leading to friction and difficulty in sliding. Use a vacuum with a nozzle attachment to remove loose dirt and particles. Follow this with a damp cloth to wipe down the tracks, ensuring all grime is eliminated. For stubborn dirt, a mixture of lukewarm water and mild detergent can be applied using a soft brush. Avoid using harsh chemicals as they can damage the aluminum surface.

Window Track Lubrication

Once the tracks are clean, the next crucial step is window track lubrication . Lubricating the tracks reduces friction and ensures smooth movement. A dry graphite lubricant is recommended for aluminum tracks as it doesn't attract dust and dirt. Apply a small amount along the tracks and test the window movement to ensure even distribution. Avoid using oily lubricants, which can gather more dirt and complicate the sliding mechanism.

Inspection and Preventive Measures

Regular inspection of your window tracks can help identify potential issues early. Check for signs of wear or damage, such as cracks or bends in the track. If you notice any problems, address them promptly to prevent further damage. Additionally, consider applying a protective wax coating to the tracks to shield them from environmental elements and reduce the risk of corrosion.

By following these maintenance tips, you can ensure that your aluminum window tracks remain in excellent condition, providing smooth and efficient operation for years to come. Regular cleaning, proper lubrication, and thorough inspections are simple yet effective ways to enhance the performance and longevity of your window systems.

Choosing the Right Aluminum Window Track

When it comes to selecting the perfect aluminum window track for your home, it's essential to consider several factors that ensure both functionality and longevity. The right track can enhance your window's performance, reduce maintenance needs, and complement your home's design. Here’s how to choose the best aluminum window track for your needs.

Consider Window Size and Configuration

Your first step in selecting an aluminum window track is to assess the size and configuration of your windows. Larger windows may require sturdier tracks to support the weight and ensure smooth operation. For instance, a two-track aluminum sliding window might be suitable for smaller, standard-sized windows, while a three-track system could offer better support and functionality for larger openings, providing additional flexibility and ventilation options.

Assess Environmental Conditions

Environmental factors play a crucial role in determining the appropriate track material and design. If you live in a region prone to harsh weather conditions, such as heavy rain or extreme temperatures, opting for tracks made from high-quality aluminum with corrosion-resistant properties is advisable. Aluminum's inherent resistance to rust and wear makes it a reliable choice for maintaining window functionality over time, as highlighted in this guide on evaluating window quality .

Ensure Design Compatibility

Another important aspect is ensuring that the track design complements your home's architectural style. Aluminum tracks offer a modern, sleek appearance that can enhance the aesthetic appeal of contemporary homes. They are available in various finishes and can be customized to match your window frames and overall decor. This adaptability makes aluminum tracks a versatile choice for different home styles.

Evaluate Track Quality

Quality is paramount when choosing window tracks. Look for tracks that are well-constructed, with smooth finishes and precision engineering to ensure longevity and ease of operation. High-quality aluminum tracks will have features like integrated weatherstripping to enhance energy efficiency and minimize drafts. Additionally, consider tracks that offer easy installation and maintenance, reducing long-term upkeep efforts.

In conclusion, selecting the right aluminum window track involves careful consideration of window size, environmental conditions, design compatibility, and track quality. By focusing on these factors, you can ensure that your windows operate smoothly and efficiently while enhancing your home's aesthetic appeal. As you explore your options, remember that the right track can significantly impact your window's performance and your overall satisfaction with your home improvement investment.

Conclusion: Enhance Your Windows with Aluminum Tracks

As we conclude our exploration of aluminum window tracks, it's clear that these components are more than just a functional necessity; they are a pivotal part of enhancing your home's overall efficiency and aesthetic appeal. Choosing the right aluminum window track can transform your windows into seamless, efficient systems that add value and comfort to your living space.

Throughout this guide, we've delved into various aspects of aluminum window tracks, from understanding their fundamental role in window systems to exploring different types and installation processes. The benefits of aluminum window tracks, such as their durability, lightweight nature, and aesthetic versatility, make them a standout choice for modern homeowners. By opting for high-quality tracks, you ensure that your windows not only function smoothly but also withstand the test of time, offering long-term reliability and performance.

Moreover, the maintenance tips provided can help you keep your tracks in optimal condition, ensuring that they continue to operate efficiently and extend the lifespan of your windows. Regular cleaning, proper lubrication, and timely inspections are simple yet effective practices that can prevent common issues and enhance the functionality of your window systems.

When selecting the right track, consider factors such as window size, environmental conditions, and design compatibility. These considerations will guide you in choosing a track that meets your specific needs and complements your home's architecture. Remember, investing in high-quality aluminum window tracks is not just about immediate functionality—it's about enhancing windows with aluminum tracks to improve your home's comfort, efficiency, and style.

In conclusion, aluminum window tracks offer numerous benefits that can significantly enhance your home's windows. By making informed choices and following the guidance provided, you can enjoy the seamless operation and aesthetic appeal that these tracks bring. Whether you're undertaking a new installation or replacing old tracks, consider aluminum window tracks as a valuable addition to your home improvement projects. For those seeking premium-quality aluminum solutions, exploring offerings from industry specialists like Suqian Sunmay Aluminium can provide further assurance of quality and satisfaction.

Frequently Asked Questions about Aluminum Window Tracks

1. How do you make aluminum windows slide easily?

To ensure smooth sliding, clean the tracks regularly and apply a silicone-based lubricant. This reduces friction and prevents corrosion, enhancing the window's operation.

2. Can you replace the track on a window?

Yes, replacing window tracks is possible and often necessary for maintaining functionality. Ensure you choose the right track system for your window type and follow a detailed installation guide.

3. What are the benefits of using aluminum window tracks?

Aluminum window tracks offer durability, corrosion resistance, and a lightweight structure, making them ideal for smooth operation and longevity in various climates.

4. What should I consider when choosing an aluminum window track?

Consider window size, environmental conditions, and design compatibility. Opt for high-quality tracks that offer ease of installation and maintenance.

5. How do I maintain aluminum window tracks?

Regularly clean the tracks with a damp cloth, apply a dry graphite lubricant, and inspect for damage to ensure optimal performance and longevity.