Sound-absorbing panels work by absorbing sound energy and reducing reflections, thus eliminating echoes and reverberation. Their effectiveness largely depends on:

Material density and porosity

Internal structure

Fire resistance and safety

Environmental performance

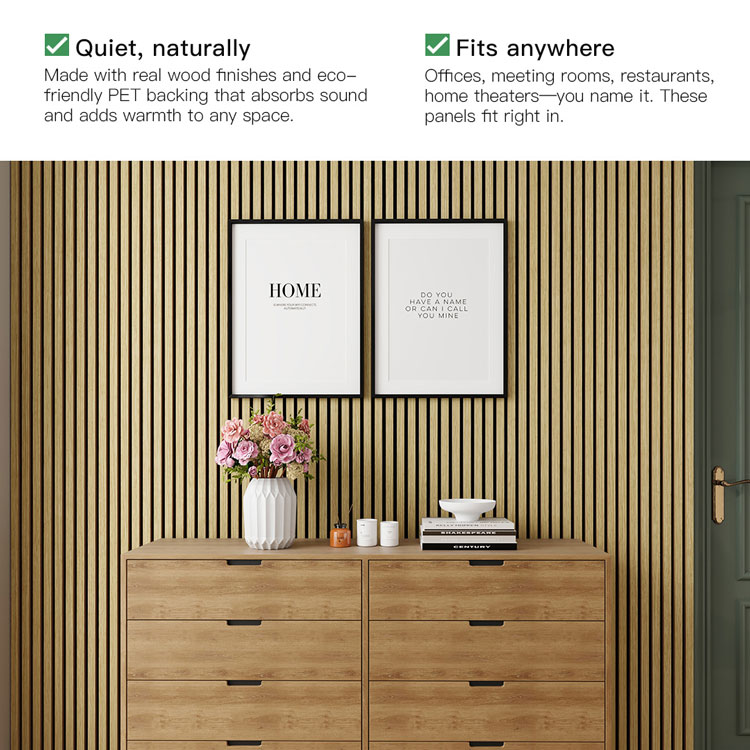

Visual design compatibility

Choosing the wrong material can lead to poor sound insulation, short product lifespan, or safety hazards.

Common Materials for Sound-Absorbing Panels

1. PET Felt (Recycled Polyester Fiber)

PET felt boards are widely used for basic sound absorption.

Advantages:

Lightweight and easy to install

Made from recycled plastic bottles

Good sound absorption for mid-to-high frequencies

Environmentally friendly and recyclable

Disadvantages:

Limited sound absorption for low frequencies

Softer surface, lower impact resistance

Functionality outweighs aesthetics

PET felt is commonly used in offices, schools, and projects with limited budgets.

2. Sound-Absorbing Foam

Sound-absorbing foam is commonly found in small recording studios and home recording studios.

Advantages:

Affordable entry-level option

Easy to install yourself

Reduces flutter echo

Disadvantages:

Weaker low-frequency performance

Will deform over time

Limited fire resistance of low-quality foam

Not suitable for high-end interior decoration

Foam is best suited for temporary or small-scale acoustic treatments.

3. Mineral Wool/Glass Fiber (Core)

Mineral wool and glass fiber are typically used inside acoustic panels, not as exposed surfaces.

Advantages:

Excellent sound absorption across the entire frequency range

High density enhances performance

Fire-resistant after proper treatment

Disadvantages:

Requires fabric or solid surface covering

Less aesthetically pleasing

Requires careful handling during production

These materials form the core of many professional-grade acoustic panels.

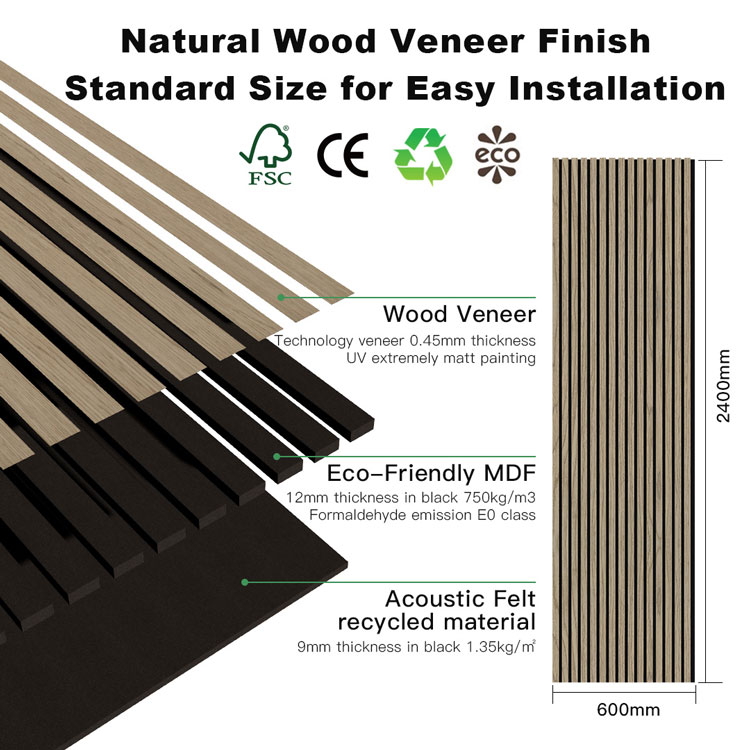

4. Medium-Density Fiberboard (MDF)

High-density medium-density fiberboard is a key structural material for high-end acoustic panels, especially wood slat wall panels.

Advantages:

Stable density ensures consistent acoustic performance

Strong structural integrity

Smooth surface for easy veneer application

Ideal for strip and perforated designs

Limitations:

Performance depends on density and quality

Low-grade MDF may release higher levels of volatile organic compounds (VOCs)

Our company uses rigorously selected high-density MDF that meets international standards.

5. Natural Wood Veneer (Decorative and Functional Layer)

Natural wood veneer plays a crucial role in wood strip acoustic panels.

Advantages:

Enhances aesthetics and interior value

Utilizes slat spacing to diffuse and absorb sound

Natural, warm appearance

Complements modern and luxury design styles

Limitations:

Vene thickness and bonding quality are critical

Requires specialized production control

When used in conjunction with acoustic backing, wood veneer offers both performance and aesthetics.