In the field of modern architecture, detachable container houses have gradually come into the public eye and are widely used. However, perhaps you may have some questions about detachable container houses when you first hear this term. This article will answer common questions about detachable container houses in detail and help you fully and deeply understand this innovative building product.

1、 Is the structure of the detachable container house stable?

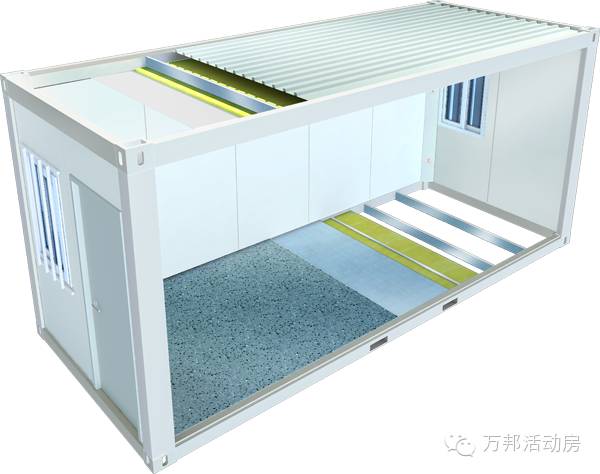

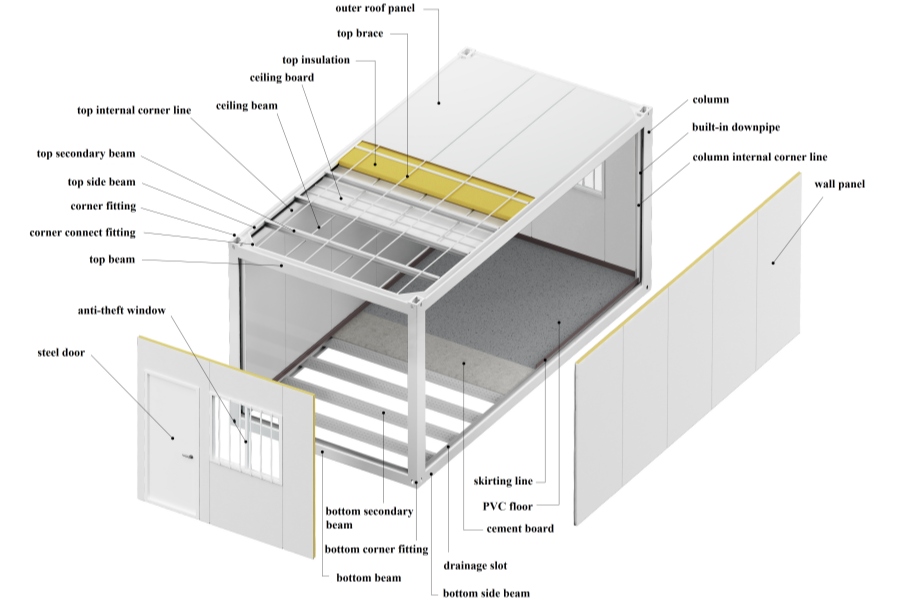

Detachable container houses use high-strength steel as the main frame structural material. This steel has excellent compression, bending and torsion resistance, and can withstand large weights and external impacts. During the design process, precise calculations and simulation tests are performed to ensure that the connections of each component are stable and reliable. For example, the corner columns, beams and other key parts of the house body are connected by special welding processes or high-strength bolts to form a solid whole for the entire frame. Provide safe and reliable space protection for residents or users.

2、Can detachable container houses withstand strong winds and earthquakes?

The design of the detachable container house takes into account a certain degree of wind and earthquake resistance. Its steel structure frame has good stability and strength and can withstand a certain degree of wind force. In terms of wind resistance design, reasonable structural design and reinforcement measures, such as adding diagonal braces and strengthening connection parts, can improve the stability of the house in windy weather. For earthquakes, its structure can reduce the damage to the house by earthquakes through its own flexibility and earthquake-resistant structural measures, such as the use of earthquake-resistant connectors, to ensure the safety of people and items inside. Ensure its safety in extreme situations, so that you can use the detachable container house with confidence, and it can provide a relatively safe space even under harsh natural conditions.

3、Is the assembly process of detachable container houses complicated? Do I need professionals to operate it?

One of the significant advantages of detachable container houses is their quick and easy assembly process. It is designed with prefabricated components, and most of the processing and preliminary assembly work has been completed in the factory. After arriving at the site, assembly mainly relies on simple tools. Compared with the months of traditional building construction,detachable container houses can be assembled and put into use within days or even hours, which greatly improves the efficiency of space construction.

4、Is the detachable container house easy to transport?

The convenience of transportation was fully considered when designing the detachable container house. Its standard and unified size specifications and modular structure make it perfectly compatible with all kinds of common transportation tools, whether it is a large-scale heavy-duty truck, a freight train carriage, or a container space on a cargo ship, it can be loaded and transported conveniently and quickly. A 20-foot container can hold 8 sets of detachable container houses, and a 40-foot container can hold 18 sets, which greatly reduces transportation costs.

5、How is the thermal insulation performance of the detachable container houses?

Detachable container houses have good performance in thermal insulation. Its walls and roofs are made of multi-layer composite materials. The outer layer is usually a weather-resistant metal sheet that can effectively resist external wind and rain erosion and direct sunlight; the middle layer is filled with high-efficiency thermal insulation materials, such as rock wool boards, which have extremely low thermal conductivity and can effectively prevent heat transfer.

6、Is the spatial layout of the detachable container house?

The detachable container house has shown great flexibility in space layout. It can be used independently as a single house according to your specific needs, or multiple houses can be spliced and combined to form space layouts of various shapes and sizes. You can design it into a warm residence, a spacious office, a fully functional warehouse, or even a creative and unique commercial display space according to actual use. Moreover, the space division inside the detachable container house is also very convenient, and the size of each functional area can be easily adjusted to meet your changing usage needs at different stages, truly realizing personalized space customization.

7、Can the appearance and interior decoration of detachable container house be customized?

Our company provides professional customized services to meet your personalized needs for exterior and interior decoration. In terms of exterior, you can choose different colors, patterns and even shapes according to the overall style of the project, brand image or personal preferences, so that the container is more coordinated with the surrounding environment, or show a unique personality charm. For interior decoration, you can customize the layout of different functional areas, choose various styles of decoration materials, such as modern minimalist style, European classical style, rural style, etc., and can also be equipped with customized furniture, lighting systems and other decorative elements.

8、How to solve the internal ventilation problem of detachable container houses?

The internal ventilation of the detachable container house is mainly solved by combining natural ventilation and mechanical ventilation. In terms of natural ventilation, it is mainly through windows, so that natural ventilation can be achieved when the air flows and fresh air can be introduced. At the same time, reasonable layout design can be used to avoid blocking the ventilation path and optimize the natural ventilation effect. In terms of mechanical ventilation, exhaust fans, fresh air systems and other equipment can be installed to enhance ventilation capacity, especially in some places with high requirements for air quality, such as living spaces, office areas, etc. Mechanical ventilation can more effectively ensure the freshness and circulation of indoor air and provide users with a healthy and comfortable indoor environment.

9、How is the price of detachable container house determined?

The price of a detachable container house varies according to the needs and budget of each person. The size and configuration of the container will have a greater impact on the price. For example, a house with a larger size, equipped with more advanced water and electricity systems, furniture and other internal facilities will naturally be more expensive. The prices of detachable container houses produced by different manufacturers may also vary. The containers produced by our company can guarantee the best configuration and service at the same price.

10.、How long is the service life of a detachable container house?

The service life of a detachable container house is affected by a combination of factors. In terms of material quality, we use high-quality steel, thermal insulation materials and decorative materials, and strictly follow relevant quality standards and process specifications during the production process. Its service life can reach 30 years or even longer. Daily maintenance also plays a key role in the service life. Regularly checking the connection of structural components, repairing damaged thermal insulation materials and decorative materials, cleaning the drainage system, etc., can timely discover and solve potential problems and effectively extend the service life of the container house.