Project introduction:

Project name: Stoney Hill Manufacturing Building ‘A’

Project owner(Yumisteel client): AllEarth Properties, LLC

Project location: Bristol, Vermont

Project designer: Cushman Design Group, inc.

Building characteristics:

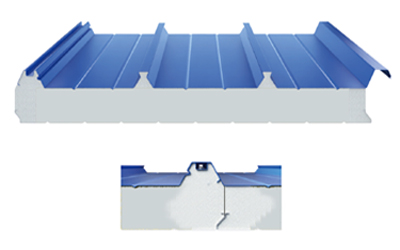

- This is a large commercial steel structural building with good insulation panels. The PIR roof and wall sandwich panels were supplied by Yumisteel.

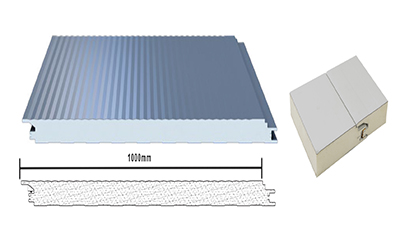

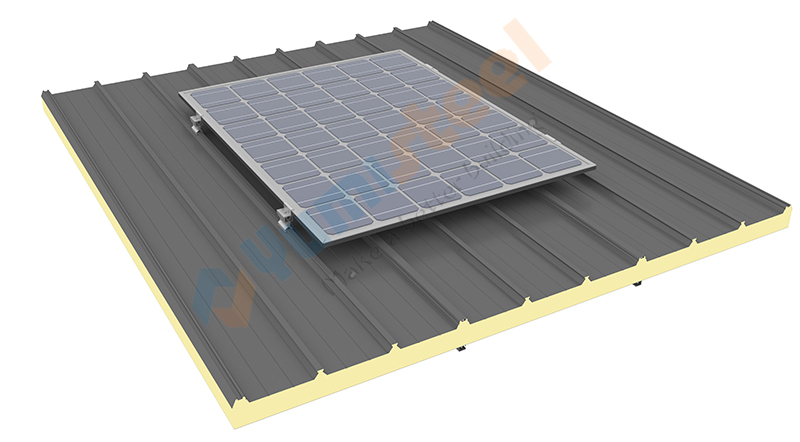

For roof, it’s using 150mm thick PIR roof sandwich panels, which are specially for installing solar system. For wall it’s using a concealed joint PIR wall sandwich panels at 100mm thickness.

|

|

| PIR roof sandwich panel type for PV system | Hidden screws joint wall sandwich panel type |

The way to fasten the solar panels with clamps on Yumisteel roof sandwich panel:

- By this project, Yumisteel also helped solve 2 problems.

1)How to spray new colors on the metal panels?

Because this building has couple meters of metal panel in green color and we can’t find very close color as per what client wanted. We offered solutions on color spray of metal sandwich panels.

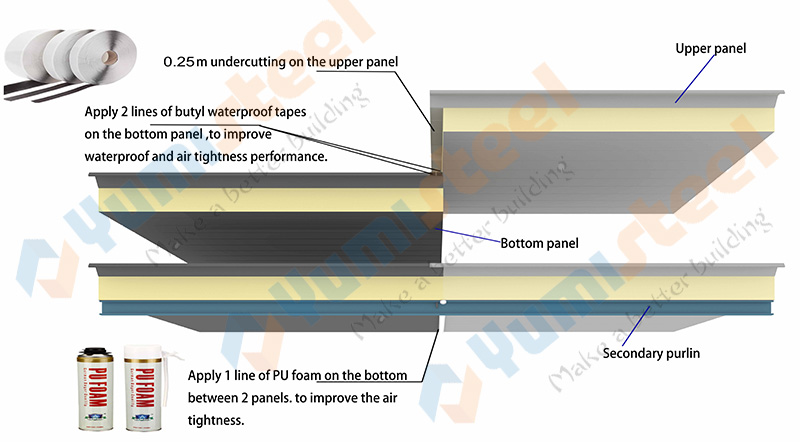

2)How to joint 2 roof sandwich panels on longitudinal direction, when the panel length is not meet up the building size?

If you also need the solutions, please contact Yumisteel team.

Architecture Awards:

This commercial steel structural building also awarded "Large Commercial New Construction Award" of Efficiency Vermont 2024.